fine screening of iron ore fines

Global Iron Ore Fines Market 2018 by Manufacturers ...

Iron ore fine is an ore powder formed by processing ore, crushing, sorting, grinding, etc. of iron ore (mine containing iron or iron compound). The worldwide market for Iron Ore Fines is expected to grow at a CAGR of roughly % over the next five years, will reach 141700 million US in 2023, from 112000 million US in 2017, according to a new ...

Iron ore conveyed

Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel. Indeed, it has been argued that iron ore is "more integral to the global economy than any other commodity, except perhaps oil".

Iron Ore Fines/Iron Ore Cargoes Early Implementation of ...

fine particles less than 1 mm and 50% or more particles less than 10 mm are classified as iron ore fines (Group A), unless they have a goethite content of 35% or more by mass, in which case they may be carried in accordance with the existing Schedule for iron .

Iron Ore Concentrate Iron Ore

Iron Ore Concentrate. Magnetic techniques also are used. The upgraded ore, or concentrate, is in the form of a very fine powder that is physically unsuitable for blast furnace use. It has a much smaller particle size than ore fines and cannot be agglomerated by sintering. Instead, concentrates must be agglomerated by pelletizing.

RTZ Iron Ore Mine, Hamersley Basin, Western Australia ...

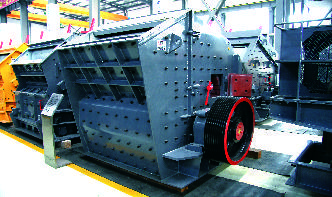

Ore is loaded into haul trucks by shovels, hydraulic excavators or frontendloaders, and transported to the primary crusher. It is then processed in a crushing and screening plant to produce fine ore and lump ore. At Marandoo, four pits are operational and others will be brought into operation in the future.

Iron Ore (Channar Joint Venture) Agreement Act 1987

"fine ore" means iron ore which has an average pure iron content of not less than 60% which will pass through a six millimetre mesh screen and which is sold without concentration or other beneficiation other than crushing and screening; "fines" means iron ore (not being direct shipping ore or fine ore) which

Msds Iron Ore Fines Crusher Stone Crushing Machine

Iron Ore Processing,Crushing Screening,Grinding,Beneficiation . Iron Ore Crushing Screening. . Iron Ore Fines/blue dust cannot be charged in the blast furnace directly since they block the passage for ascending gas inside the fee. Click Chat Now

Maximizing high Alumina Iron Ore fines consumption in ...

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast furnace. The final product.. The final product.. To read full article Subscribe Steel 360 June'17 Issue >> Subscribe Now

Rinehart faces big bill for Roy Hill overhaul The Australian

The changes approved at Roy Hill also extend to the addition of a crushing facility to convert lump ore into fines, and a screening facility that can separate out ultrafine highgrade iron ore ...

Royalty on Iron ore An overview with a special reference ...

These summaries show that Ukraine has the largest reserve of iron ore at 30 billion tonnes followed by Russia, China, Australia, Brazil, Kazakhstan, India and USA. In terms of iron content, the largest reserve is in Russia followed by, Australia, Ukraine, Brazil, China, India and Kazakhstan.

NMDC Limited Bailadila Iron Ore Mine,Bacheli Complex

A highly mechanised wet screening plant and facilities for stacking, reclaiming and loading (2500 t/ hour) of lump ore into railway wagons. In 1987 mechanised handling system of reclamation and wagon loading of fine ore with a capacity of million tonnes per annum was also added to meet the increasing demand of fines in the steel industry.

FACTORS INFLUENCING MATERIAL LOSS DURING IRON ORE .

competent materials ( iron ore concentrate pellets) tend to produce fines solely by abrasion. In either case, the generation of f ines is unwanted and can lead to material loss es and emissions of fugitive dust. In the iron ore concentrate pelletizing industry, the Abrasion Index (AI) is used to indicate the abrasion resistances of pellets.

Iron ore loading causes of iron ore liquefaction during ...

Iron ore fines liquefied after transportation in the same hold In other cases cargoes loaded have been found to have a moisture content in excess of the Transportable Moisture Limit (TML) prior to the ship's departure and the ships in question have been prevented from sailing by the local authorities until the situation has been rectified, leading to substantial delays.

Iron Ore Fine Manufacturers | Suppliers of Iron Ore Fine ...

manufacturers and suppliers of iron ore fine from around the world. Panjiva uses over 30 international data sources to help you find qualified vendors of iron ore fine.

Granulation of Coke Breeze Fine for Using in the Sintering ...

There are huge amounts of coke fines produced inside the Integrated Iron and Steel plant. during coke transportation, handling and crushing of coke for use in the sintering process. Granulation is one of the agglomeration processes which convert the ore fines into granules of suitable size.

Pellatization of Iron ores SlideShare

Aug 13, 2014· Pellatization of Iron ores 1. PELLATIZATION OF IRON ORES Muhammed Labeeb 2. Engr 241 Pelletizing is the process of compressing or molding a material into the shape of a pellet Process objective is to transform fine iron ore concentrate into pellets suitable to feed Blast Furnace or Direct Reduction plant or COREX. Palletisation was invented to make use of Blue dust and ultra fine .

Fine particle processing of iron ore slimes from Orissa, India

Abstract The fine particle of processing of slimy tails of iron ore wash plant tails have been addressed either by flotation or wet high intensity high gradient separation. This paper furnishes a few case studies of fine particle processing of some iron ore wash plant slimy tails spread across, Orissa. The

Iron Ore InfoMine

Iron ore fines processing plant Low grade fines with high (alumina and silica) clay levels We effectively processed this waste fraction to provide a saleable market grade iron ore. Our main focus was around not only decreasing the alumina and silica levels but also ensuring maximum levels of yield were achieved. Maithan Ispat Jai Balaji

Mining Industrial Solutions International

Mining Industrial Home / Markets Served / Mining Industrial DSI provides Corporation's complete line of high frequency vibrating machines and screen surfaces used to screen a wide variety of wet or dry fine materials in the range of 3/8 inch to 400 mesh (10 mm to 38 microns).

IRON ORE FINES

• Iron ore fines are a product of the screening of iron ore • They are used to produce sinter or pellets in the steel industry

Iron Ore Mineral Technologies

Iron Ore Giving You Confidence. With an unparalleled depth of knowledge in fine minerals the world's largest producers rely on us as their 'go to' partner to beneficiate Iron .

Iron Ore Fines Manufacturers, Suppliers Exporters in India

Iron Ore fine is Minerals or Rocks Deposit in Which Iron Was Concent. We bring to customers some highly authentic Indian iron ore fines. Our fine iron ore is widely appreciated in .

Experimental Study of Stockpiles of Iron Ore Fines

versus the Iron Ore Fines Stockpile Scale Model . Samples with 50 kg of pellet feed (iron ore fines) were used to form the scale models of the stockpiles set out in the iron ore mine production yards. The density value for the sample is g/cm. 3. This sample was called sample 1 in this article. We applied the formulation [1] for the ...

Utah Online Court Payments |

Pay District Court and Justice Court fines and other payments online by case number and court name or by citation number. Make Juvenile Court payments by case number, name, and date of birth. ... Court Fine Payments Resources. ... Please visit GoodHire for all your employment screening needs.